No matter what kind of scheme is adopted for offshore oil and gas fields, it

is necessary to transport oil and gas from the inside of the formation to the

platform, FPSO, or onshore terminal. Laying submarine pipelines is the most

direct and effective transportation method. Submarine oil and gas pipelines are

the "lifeline" of offshore oil and gas production systems. The longest submarine

pipeline in the world is the Langled pipeline from Norway to the United Kingdom,

with a total length of 1,200 kilometers. It was put into operation in 2007. The

world record for the depth of the sea where the pipeline is located is 2775

meters, which was created by the "Solitaire" pipelaying vessel. At present, the

submarine oil and gas pipelines laid in China exceed 6,000 kilometers. The

longest submarine pipeline is the Yacheng 13-1 gas field, and the gas pipeline

is 778 kilometers long.

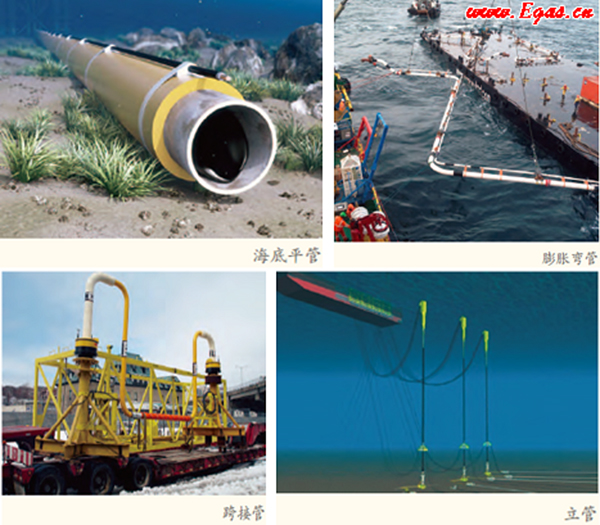

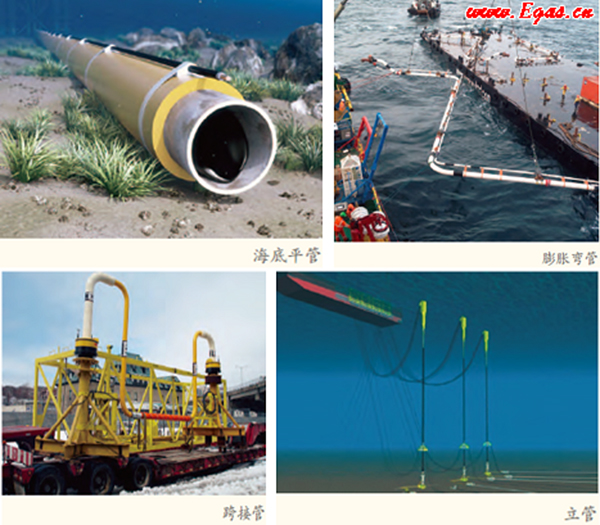

What does a subsea oil and gas pipeline look like?

Submarine pipes are pipes that are laid on the sea floor and continuously

transport oil, gas, and water. For example: Offshore oil and gas facilities are

all valuable "points". Only by connecting "points" through "lines" such as oil

and gas pipelines can a complete system be formed and the overall value of the

production system be brought into play. Submarine pipelines mainly include flat

pipes, expansion elbows, and risers. Submarine flat pipes are laid on the sea

floor and are the main force for submarine oil and gas transportation. Expansion

bends are used to connect flat subsea pipes to risers. Affected by the

temperature difference of seawater, the steel pipe has the phenomenon of thermal

expansion and contraction, and the expansion bend can compensate for the change

in the length of the sea pipe. The riser is a vertical pipeline on the sea

floor, connecting the flat sea tube to the offshore production facilities. Deep

water risers usually stand in the water in a free state, such as top

pre-tensioned risers (TTR), steel catenary risers (SCR), flexible risers, tower

risers, and so on. In addition, a crossover pipe is also necessary, which

connects the tree and the production manifold. According to the different output

(oil, gas, water) and output of the oil field, select the corresponding pipe

diameter and structure of the subsea pipe. Theoretically, the larger the output,

the thicker the pipe diameter.

In order to prevent the hydrates formed by deep water, low temperature and

high pressure from blocking sea pipelines, thermal insulation pipelines are

needed; while offshore heavy oil needs to be transported after the platform is

heated, it is necessary to use hot oil transportation technology and thermal

insulation pipeline structure. Electric heat tracing subsea pipe adds "warm

baby" to the subsea pipe. In order to increase the stability of the pipeline,

concrete counterweight sea pipes emerged at the historic moment.

The different materials of the submarine pipe determine the production cost,

anti-erosion ability, gravity requirements and performance during welding. At

present, carbon steel API 5L X56 and above are generally used.

Note: If you found anything violating your copyright, please contact us, we would remove them as soon as possible.