There are many design considerations to complete a submarine pipeline, and

the installation and construction is to overcome all difficulties. The first is

that the operating environment is in the ocean. Not only is the operating space

severely restricted, but the complex and changing sea conditions will also bring

great challenges to normal construction. In addition, the seabed environment is

complex, not just a flat river. It is composed of various topographic features,

such as high seamounts, rolling hills, long ridges, and deep trenches. We can't

transform the seabed geomorphology like laying pipelines on land, so no matter

the design or construction process, the consideration of laying submarine

pipelines is very complicated. The problems of low temperature, high pressure,

high salinity, undercurrent surge, hydrate blockage, pipeline corrosion, and

impact loss will continue to exist. The coexistence of these problems makes the

laying of submarine oil and gas pipelines not only an engineering problem, but

also a scientific problem.

So, how is the submarine pipeline laid? For construction operations, water

depth is the biggest influencing factor, and pipe laying operations are very

different depending on the water depth.

(1) In places close to the shore and in shallow water, the winch can be used

to directly pull the sea pipe to the land.

(2) Pipes can be laid in the shallow sea area and far away from the shore by

way of laying down and welding at the same time. S-Lay (S-type laying method) is

mainly used: the submarine pipeline enters the water through the stern holding

frame, forming an S-shaped curve and laying into the seabed. During the pipe

laying operation, three artifacts are needed on the ship-tensioner, stinger and

welding line. The tensioner is used to fix the sea pipe, like a big clip to hold

the sea pipe. The custody rack is used to control the laying direction of the

sea pipe. In addition, due to the limited space for offshore operations, laying

a submarine pipe requires a professional fleet to cooperate with each other to

complete the construction, and the cost is 1 to 2 times higher than that of the

land under the same circumstances.

(3) Pipe laying operations in deep water areas increase the water depth,

resulting in an exponential increase in construction difficulty. The increase in

the length of the submarine pipe leads to an increase in weight, which requires

the pipelaying vessel to withstand greater tension. At this time, the J-Lay

method is used for construction. J-Lay (J-type laying method): The submarine

pipe leaves the pipelaying vessel in a near-vertical form, and descends along

the vertical bend until it is laid into the seabed. The overall pipeline is "J"

shaped, suitable for hundreds of meters to thousands Meters in the deep sea

area.

(4) With the continuous development of new technologies, the form of offshore

pipe laying operations has been continuously improved. For submarine pipes with

small diameters and slightly weaker strength, they can be manufactured on land

and directly wound on drums, and then transported to the sea by pipelaying

ships. This operation is called Reel-Lay (rolled pipe laying operation) . At

present, the coiled pipe laying ship can be divided into two types of horizontal

and vertical. For horizontal coiled pipe laying ships, the axis of rotation is

perpendicular to the deck of the pipe laying ship, and S-type laying is used

(usually used in shallow water), which is often used for laying umbilical

cables; for vertical coil pipe laying ships, the axis of rotation and the pipe

laying vessel The deck is kept level and is laid in a J-shape, which is often

used in deep water. Of course, which operation method to choose in the end not

only needs to consider the water depth, but also combines the comprehensive

factors such as operation cycle and operation cost.

Steps for laying submarine pipes on the seabed:

Take the most common S-shaped pipe laying operation as an example to

introduce in detail how the submarine pipeline is built.

(1) Preparation stage. The preparation stage includes the placement of the

pipelaying vessel, the installation of the stinger, the inverted sea pipe, the

initial connection of the sea pipe, and the installation of the initial head of

the sea pipe. In shallow water, the starting joint is usually fixed on the

jacket, and then the pipe is started. This method is more economical.

(2) Submarine pipe welding operations. The sea pipes need to be welded

together one by one and then lowered to the bottom of the sea. The welding

process is crucial: transported to the processing workshop through the rollers,

and then beveled, degaused at the pipe end, preheated the pipe section, welded

paired, various welding (bottom welding, filling welding, internal welding, cap

welding), nondestructive Flaw detection, sand blasting, coating and sealing,

foaming and other dozen processes.

(3) The sea pipe enters the water. The pipe laying ship moves forward, and

the sea pipe enters the water. After the pipe end of the submarine pipe reaches

the mud point, it is laid while welding and enters the normal pipe laying

operation stage. When severe weather is encountered during pipe laying or other

unexpected conditions affect the normal operation of the laying of the sea pipe,

the pipe needs to be temporarily abandoned. When discarding the pipe, the

temporary discarding pipe head is welded and connected by A / R winch steel

wire.

(4) End the operation of laying the pipe section. When the submarine pipeline

is laid near the riser installation position, the laying operation is ended,

which is the same as the abandonment operation.

(5) Connection of riser and expansion bend. The operation of the submarine

flat section is completed. At this time, the distance between the submarine

pipeline and the riser needs to be measured underwater to customize the

expansion elbow. The expansion elbow adopts flange connection. Shallow water

areas can be manually dived for subsequent connection work. When the water depth

is greater than 50 meters, saturated diving operations are used.

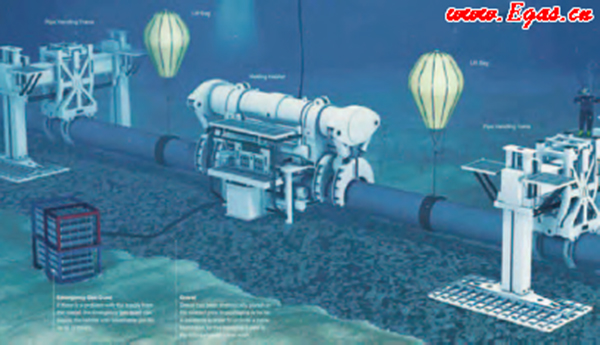

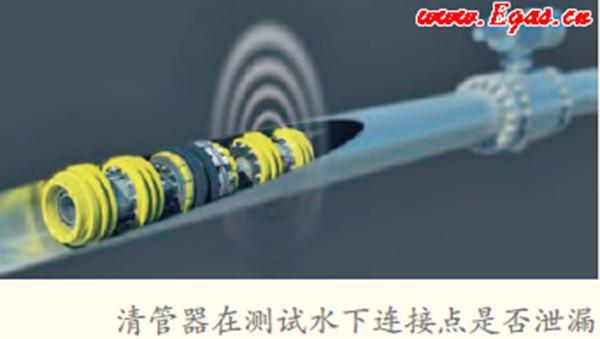

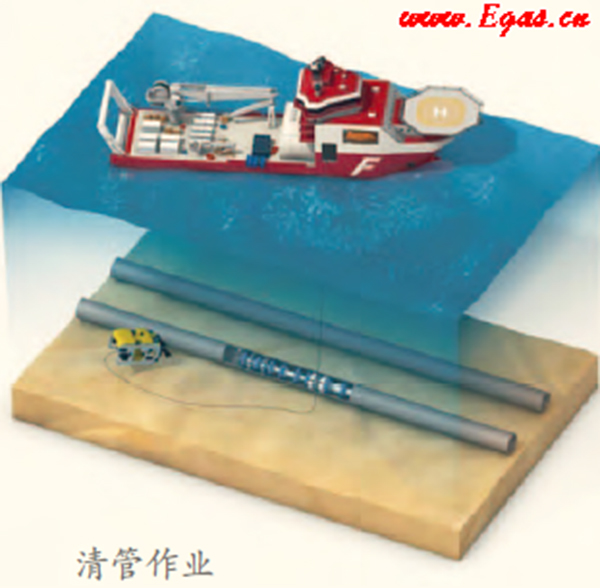

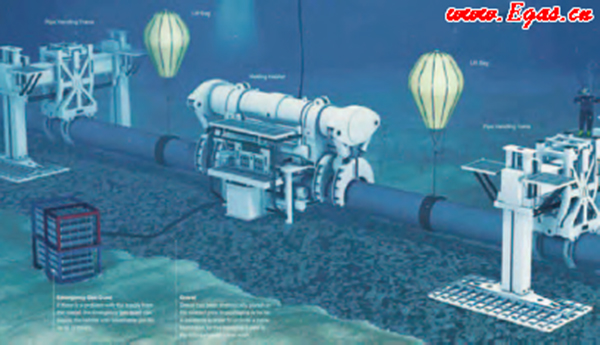

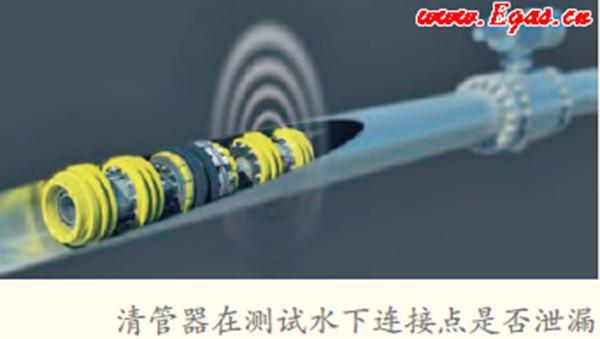

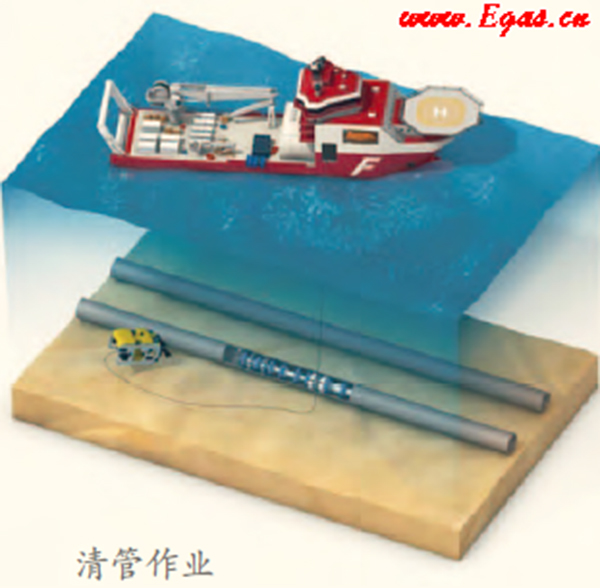

(6) Pressure test and drainage of pigging of submarine pipelines. After all

pipeline connections are completed, pigging and pressure testing are required.

The pigging operation is to clean the inner wall of the pipe and measure whether

the pipeline has buckling deformation. A commonly used instrument is a pig. The

test pressure generally needs to exceed the design pressure to test whether the

underwater connection point is leaking, and then the submarine pipe is drained

or dried.

(7) Protection and fixation of submarine pipelines. After the submarine pipe

sinks to the bottom of the sea, waves, currents, and anchoring of nearby ships

will endanger the safety of the submarine pipe. The most serious impacts are

fishery activities. The anchoring of fishing vessels, the destruction of the

flange connection points by fishing nets, etc., so certain protective measures

are required : ① For the flat pipe section, a trencher can be used for trenching

and burying. The method is to lower the trencher to the bottom of the sea, ride

on the sea pipe, lift the sea pipe, and start digging a trench, like a plough

for farming, with a depth of 1 to 2 meters, and then bury it for backfill.

②Adopt protective measures such as cement pads and fixed press blocks. The cost

of manufacturing and laying of cement cushion blocks and fixed pressure blocks

is high, so it is only used at the joints of risers and expansion bends.

(8) Pipeline repair. Even if the protection is complete, it is difficult to

completely prevent the occurrence of blockage, leakage and failure of the sea

pipe. Once the sea pipe is blocked, the pig can be used for pigging operations.

For the pipeline section where corrosion, leakage or pigging ball cannot be

dredged by sea pipe, cut the damaged sea pipe and replace the connection. For

areas with shallow water depth, you can salvage it and re-weld it. In areas with

deeper seawater, ROV underwater operation is used to cut off the sea pipe and

connect it with mechanical means such as flanges and clamps. At this point, the

laying of a complete submarine pipeline was successfully completed.

Note: If you found anything violating your copyright, please contact us, we would remove them as soon as possible.